Tips for building you own swimming pool quick and easy

Published: Do it yourself // Published 23.09.2019

Building a swimming pool in your garden:

For such a challenge project, you have 2 options: a DIY type of swimming pool or if you plan to have a larger swimming pool, simply hire a company with a proven history in building swimming pools.

Here are the main steps for building an inground swimming pool:

1. Choosing a model for your swimming pool: an inground swimming pool can be completed in many ways, installing walls from steel, concrete or polyester on a cement bottom or placing in a special excavated pit a cage from fiberglass or polystyrene. Choosing between this options is one of your first decisions, based on personal preference, yet reflecting your backyard particularities.

2. Obtaining the building permit, issued by city hall.

3. Next, it is recommended to have a project, before moving on to execution stage, project which should be designed by an engineering desing company. This project will serve as a base for initial measurements and digging works.

4. Initial measurement: after choosing the location, deciding on the type of swimming pool and its shape, we continue with measurements and marking off the ground.

5. Ground preparation: this stage is necessary and requires, among other things, removing plants from the surface, mainly trees and roots. Depending on location, level the ground (a slope ground requires complex machines for levelling) and remove stones from the surface.

6. Digging, an operation carried out with custom machines, according to your execution project. Build the pool bottom and create slopes. You can also have a stair shaped wall.

7. Leveling, operation carried out for both side walls and bottom. You can level pool walls and install wooden boards there, then pour gravel over your pool bottom.

So far, we have standard operations for any inground swimming pool. Next stages depend on your type of swimming pool and we will perform the following operations:

A. Natural Swimming Pool

The natural swimming pool is typical for gardens and residential backyards. When building natural swimming pools you should focus on flora and fauna biodiversity, avoiding the typical garden lawn with standard design. The main requirement of a natural swimming pool is giving up on classic water purification treatments. During design phase it is selected a system consisting of a basin associated with a water regeneration zone or one with several pools. Basin walls are shaped to our preference and left unfinished if possible.

photo source: wagnerswimmingpools.com

If ground wall are water absorbent, then surface is covered with a sealing foil, concealed under a gravel bed. The benefit of this foil comes from prevention of underwater plants development, however, such a pool is deprived of its natural look. You don’t have to take care of pool rims, only create a smooth passage to the rest of your garden, no space separation needed. Refreshing your water might create an imbalance for flora and water pH. You can build such a swimming pool on your own, including as basin with decorative purpose.

B. Inground gunite concrete swimming pools

Because of gunite operation benefits (high density of concrete, providing hardness and superior waterproofing features), it surged in popularity. After initial operations we need to:

1. Install the piping (first part)

2. Build support walls (usually from brick) and stairs.

3. Install the reinforcing mesh and concrete steel bars.

4. Pressure spraying of concrete (gunite or shotcrete).

photo source: i.pinimg.com

A very popular operation, shotcrete is currently considered for such applications, more suitable than vibrated concrete technology. Some of the benefits of shotcrete includes the fact that allows any size and shape of the pool wall.

1. Large swimming pools are completed with this technology. There are 2 shotcrete technologies: dry application and wet application. Both can be used for making a swimming pool, yet dry application is more popular. Shotcrete can be executed directly on natural walls (after reinforcing), as well as on brick walls (more commonly found). Because of operations and equipment used such a method for building swimming pools will not work as DIY system and you will need to work with a company with proven experience in the field.

2. Installing piping and accesories

3. Installing electrical installations (lighting, heating, etc.)

4. Interior cladding, made with different materials, best with glass tile, natural stone mosaic or medium size tiles of marble, travertine, slate, granite.

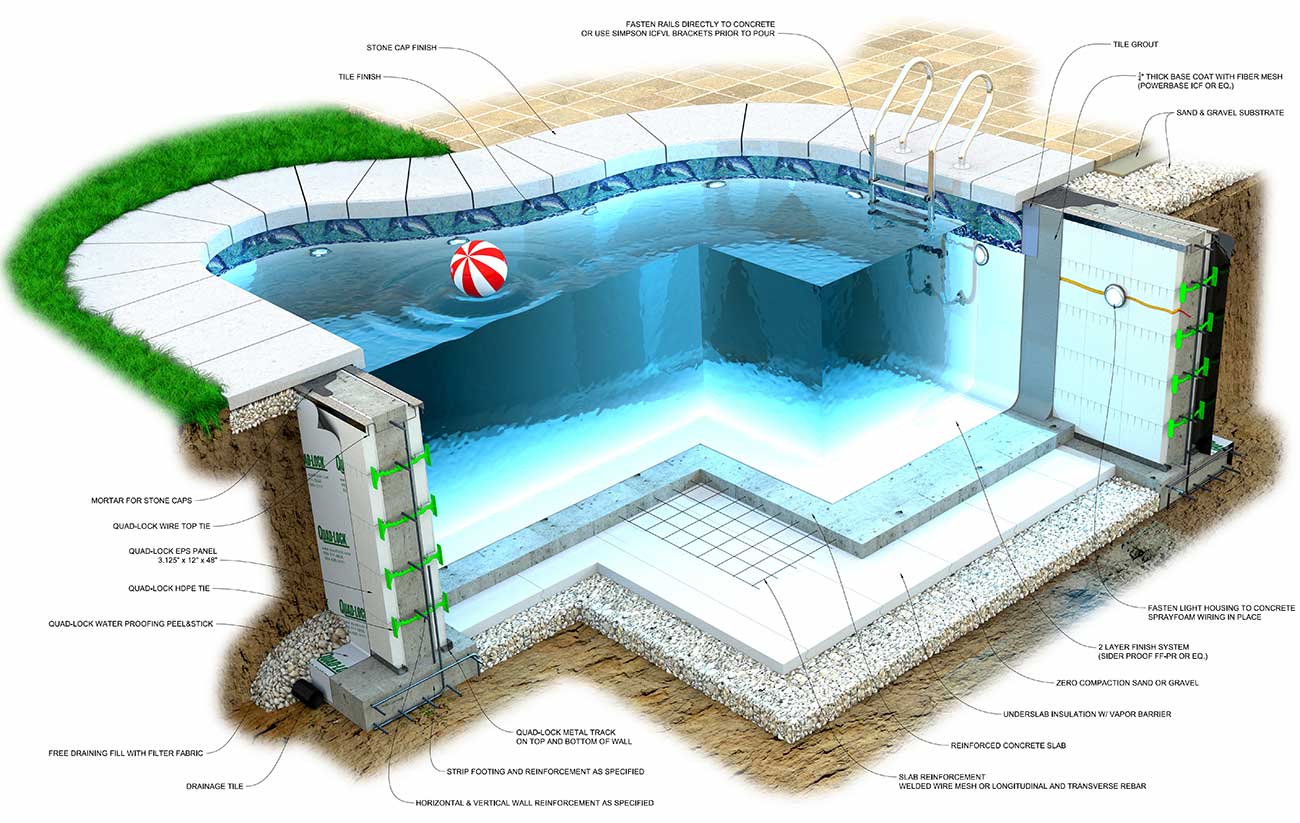

C. Inground swimming pool with polystyrene walls

1. Partial installation of piping, electrical installation, filtration and heating systems.

2. Installing reinforcement nets and metal studs for installing polystyrene walls.

3. Pouring sole plate over bottom of the pool.

photo source: sider-crete.com

4. Building walls. Polyester walls serve an essential purpose as thermal insulators. Cut polystyrene where swimming pool accessories are installed (e.g. skimmer). Install the skimmer. Uphold walls and pour concrete.

5. Install stairs.

6. Complete installing piping and hoses.

7. Install liner (waterproof foil, lining).

D. Inground Pool with steel walls

1. Partially install the piping.

2. Install galvanized steel walls, fasten them, and then attach them to each other for supporting the ground walls and leveling. Swimming pool accessories (light, heating, filtration, food) are installed at this stage.

photo source: siriusmetais.com.br

3. Pouring sole plate, for supporting the side walls and foil. Install stairs.

4. Installing waterproof foil over walls and bottom. This foil keeps water in the pool.

E. Inground swimming pool from polyester or glass fibers

Such a swimming pool has a box made of polyester or fiberglass, it is cheaper and easier to install. Also, it is recommended for a steady ground.

1. After digging and preparation, pour a mixture of gravel and sand in the pit.

2. Level for ensuring a steady foundation. Have side grooves for piping.

3. Lay the swimming pool in position. This is massive and requires using a crane.

4. Install piping for power and drainage. Cover and level the remaining surfaces.

After building or installing a swimming pool, PIATRAONLINE assists us with the following steps:

1. Installing travertine stairs, from Latte Travertine, chiseled and brushed or other models

2. Take care of the area around your swimming pool. You can clad it with honed natural stone for slip-resistance.

3. Install kerbstones, with pre-assembled solutions or clad it with stone tiles. Classic Cross Cut Travertine and Latte Travertine are practical solutions, yet not the only solutions

4. Exterior cladding, for a smooth passage between pool and exterior. Pool coping around swimming pool are cladded natural stone having slip-resistant finish (marble, travertine and slate, granite with honed or brushed finish).

For the moment there are no comments from our users.

Write a comment or a review!